DesignQ Winnipeg Embraces Technology to Improve Customer Experience

Winnipeg, MB - When clients enter the DesignQ Winnipeg design centre, they see a wide range of exciting options for finishing and ideas for decorating their new homes. What they don’t see is the behind-the-scenes work that goes into ensuring they have the best customer experience possible.

Recently, DesignQ Winnipeg has stepped up in a big way to leverage technology to improve internal processes and product offerings and ultimately, the customer’s experience. A significant motivator to kick innovation projects into high gear

was COVID-19. Sheri Henkel-Moore, Manager, DesignQ shares a few examples of note.

Recently, DesignQ Winnipeg has stepped up in a big way to leverage technology to improve internal processes and product offerings and ultimately, the customer’s experience. A significant motivator to kick innovation projects into high gear

was COVID-19. Sheri Henkel-Moore, Manager, DesignQ shares a few examples of note.

“Since the pandemic hit,” Sheri said, “we can’t have open houses. So, we needed to be able to provide our customers with something so they can see what selections are available before they end up in our design studio and are expected to make a lot of choices within a short amount of time.”

Working along side the Marketing Managers from both Sterling Homes and Broadview Homes and Kensington Homes and Foxridge Homes, DesignQ has created both building standards and upgrades catalogues. The catalogues allow customers to pre-shop their selections so to speak and equip sales agents with immediate answers to standards vs upgrade questions.

Internally, a benefit of the building standards binders is its function as a training manual for new designers joining the DesignQ team to understand the standards for each business unit brand.

Another operational excellence project that has been in the works is digitizing forms. Currently, designers manually write in pre-printed forms when clients are making selections. To improve the process, the team has been working to create a digital form that designers can use on an iPad while going through the design centre with clients. It’s a change that will lead to less paper and reduce errors that sometimes result from illegibility.

When it comes to applying technology to better space utilization, this is where visitors to DesignQ will experience the most significant positive impacts.

Through data analysis on product selection and inventory, DesignQ Winnipeg has the confidence backed by data, to streamline product offerings.

In the case of flooring selections, for example, data on purchasing trends over multiple years was used to narrow down flooring options by up to 50 per cent for some lines. Fewer options mean that space can be freed up for other new inventory and customers don’t feel as overwhelmed when making choices. So far, some of the freed-up space has been used to display larger samples of exterior products, such as stucco.

In the future, some of the space will likely be used for larger exterior siding samples as well, and Sheri would also like to have an area dedicated to smart home technology, where clients can have a hands-on experience using touch pads and other fun and functional tech.

Inventory data has also helped with improving the plumbing fixture area of the design centre by allowing product to be organized into “families” (such as a series of a brand), along with being grouped by type (kitchen, bathroom, etc.), and finally finishes. This is much more visually appealing for customers and much easier for designers to work with.

Going hand in hand with leveraging inventory data has been transferring these same best practices to asset management.

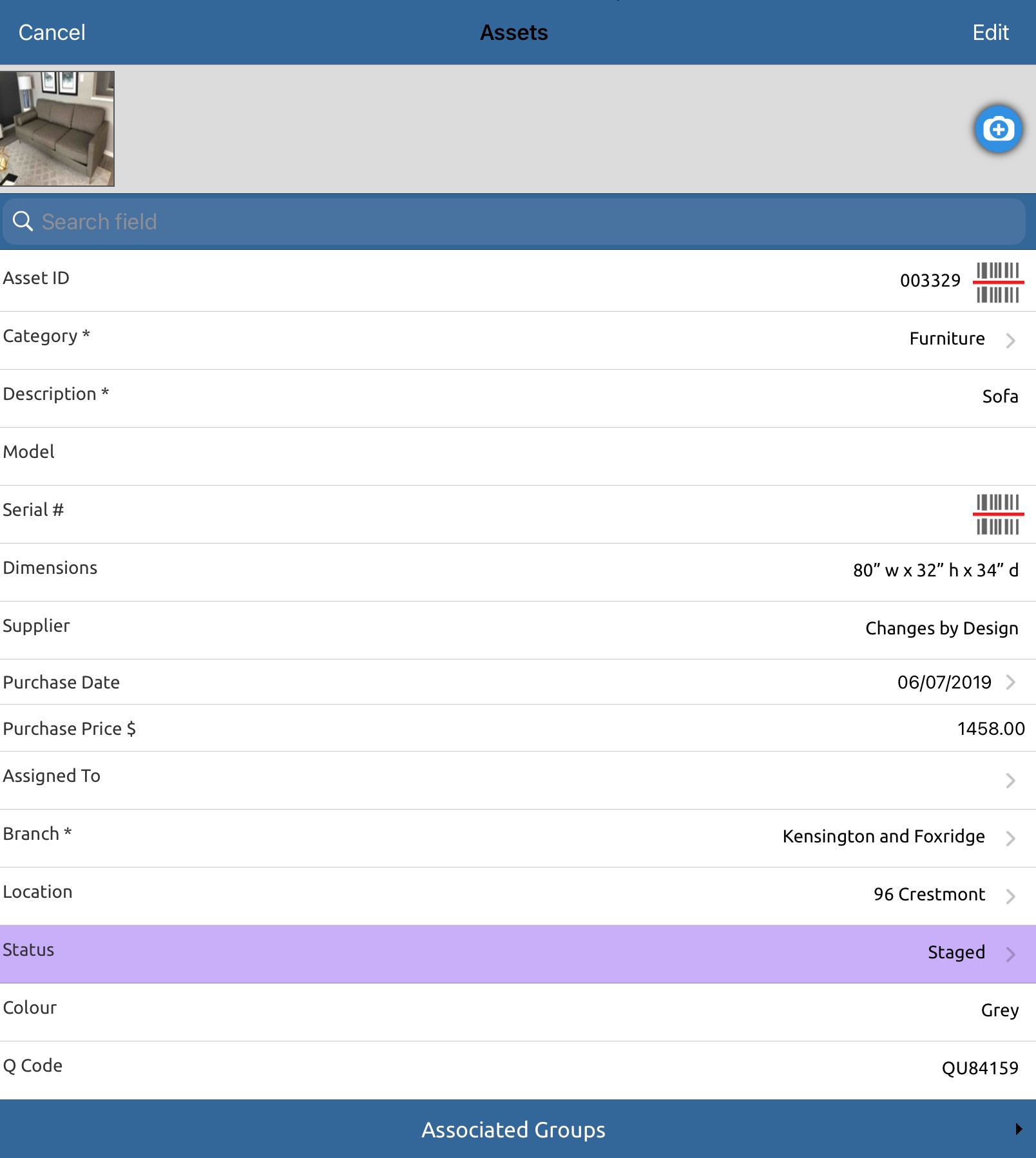

Sheri and her team took over asset management for five builders’ show homes in November 2020, and a system called Asset Panda has proved to be extremely useful in this regard. The assets include things like large pieces of furniture, lamps, rugs, and artwork.

“To date, we have built around 3,000 assets,” said Sheri. “We know exactly what we have, it has an image attached to it, it has all of the dimensions, it tells us the location of the item, and we can now transfer it when it goes from one show home to another.”

Asset Panda has allowed the team to identify which storage pods can be emptied, helping Qualico save money and reduce the space required for storing items. The team also has compiled data on costing and depreciation, which helps inform purchasing decisions when items are added. Overall, Sheri estimates that the project should be fully complete within the next four weeks.

What’s important to note throughout all these projects, is the spirit in which Sheri and her team is ready, willing, and able to test new technologies and processes and share what’s been learned.

“There’s always something that can be learned,” said Sheri. “The other DesignQ locations are really excited to learn about Asset Panda and how it can work for them. I know other business units will end up benefitting from these projects as well.”

Published: May 2019

2018 - A Year in ReviewPublished: May 2019

2018 - A Year in Review- Single-Family Homes

- Multi-Family Homes

- Communities

- Commercial

- Building Materials and Services

- Property Management

Let us help you direct your questions to the right team at Qualico.